Radiant tubes are essential components in industrial furnaces, ovens, and kilns, serving as tubular heating…

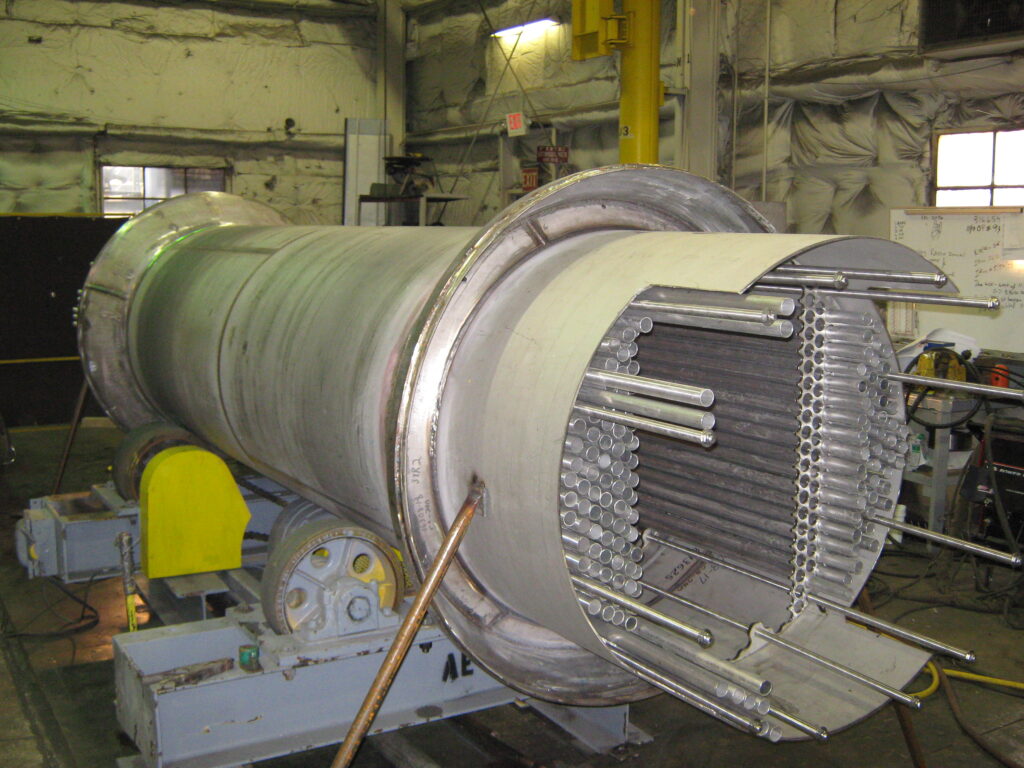

Heat Exchanger Fabrication for Diverse Industrial Applications

Alloy Engineering specializes in the fabrication of ASME (American Society of Mechanical Engineers) heat exchangers. Our offerings include a range of heat exchanger types, such as shell and tube heat exchangers, and air-cooled heat exchangers. Alloy Engineering’s capabilities extend to custom design, fabrication, and testing of heat exchangers for diverse industrial applications.

Applications:

- Petrochemical industry

- Chemical processing

- Power generation

- Oil and gas industry

- Renewble Energy

- BioGas

- Pharmaceutical manufacturing

Why work with Alloy Engineering?

- ASME Certification: Alloy Engineering’s heat exchangers meet rigorous ASME standards, ensuring high-quality fabrication.

- Alloy Engineering is an accredited ASME facility with certification stamps U & S. We are also certified to NBIC and maintain a R Endorsement.

- Customization: We offer custom design solutions tailored to specific industrial needs.

- Expertise: With years of experience, Alloy Engineering has expertise in fabricating heat exchangers for various industries.

- Quality Assurance: Our company prioritizes quality control and testing to guarantee the reliability and performance of their heat exchangers.

Considerations when Choosing a Fabricator:

- Material Expertise: Ensure the fabricator has experience working with materials suitable for your application.

- Compliance: Verify adherence to industry standards and certifications.

- Customization: Assess the ability to provide tailored solutions for specific industrial needs.

- Testing and Quality Control: Evaluate the fabricator’s quality assurance processes.

In summary, heat exchanger fabrication involves the creation of devices crucial for various industrial processes. Alloy Engineering offers a range of solutions with a focus on quality, customization, and adherence to industry standards. When choosing a fabricator, consider a manufacturer that can fabricate a heat exchanger specific to your application with the best lifetime value. Contact Alloy Engineering.

Copyright

Copyright