Industrial fans and blowers play a critical role in maintaining optimal operational efficiency within high-temperature…

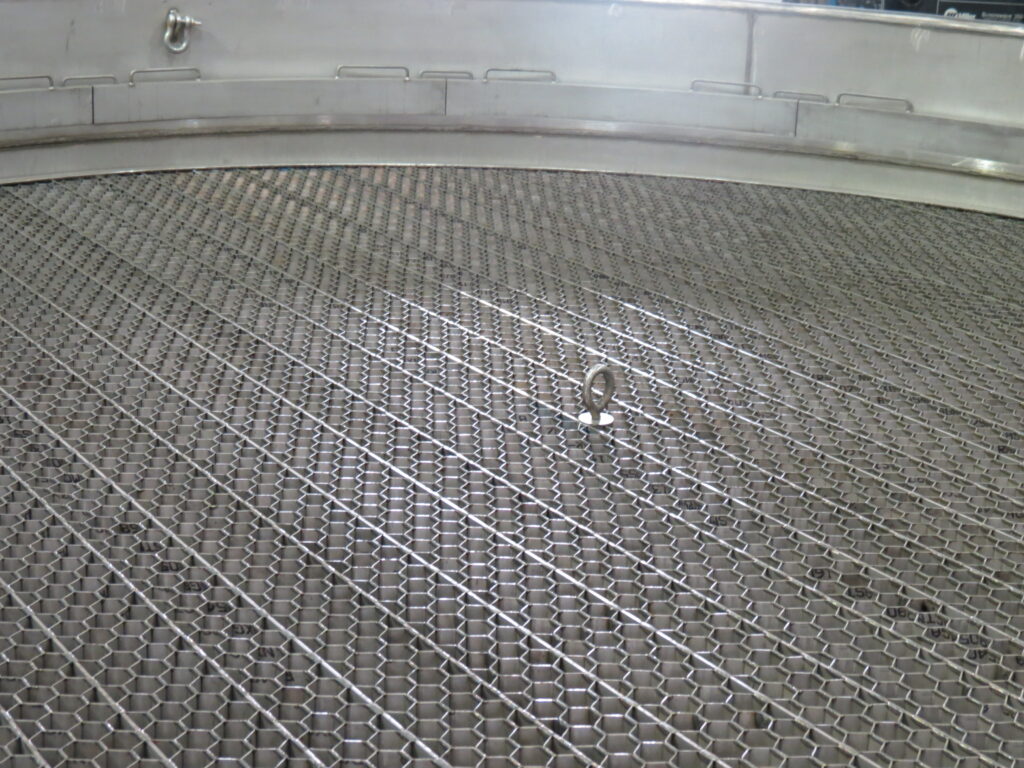

Nitric Acid Catalyst Baskets: Maximizing Performance

Material selection is a primary factor when considering a replacement for a catalyst basket. While there are many alloys capable of performing adequately in the severe environment typical of nitric acid production, selecting the one that gives optimal performance for your specific operation can be difficult. Local conditions and operating philosophies can significantly affect the mechanical performance. Take creep strength for instance, how often does heat distortion cause sealing problems in basket flanges thereby resulting in bypass of process gases? This condition is not only dangerous, but costly in the form of inefficient operation.

Consider also the distortion often found in catalyst support grids which can cause support bars to buckle and fall out of place during operation. The uneven weight distribution and low spots in the catalyst screen that result from this condition can reduce the life of this costly commodity as well as affect operating efficiency. The increased operating costs associated with this can impact profitability as well as the ability to effectively compete in the market.

Alloy Engineering’s highly experienced team of technical experts can assist in material selection to ensure peak performance of your nitric acid catalyst baskets and support grids. Please contact us today for more information.

Copyright

Copyright