Radiant tubes are essential components in industrial furnaces, ovens, and kilns, serving as tubular heating…

The Solution… Nitric Acid Reboiling

THE REPAIR

From discussions with our customer, we decided on the parts that needed to be replaced. Alloy Engineering ordered the material and manufactured the parts. The parts arrived on site within 5 days of the initial call. Along with the parts, Alloy Engineering wrote a repair procedure for the removal and installation of the replacement nozzle. We also thought it would be a good idea to have our General Manager supervise the repair.

The materials in question are an explosion bonded 304L / carbon steel vessel shell and a 304L nozzle. Most fabrication companies are not familiar with explosion bonded materials and it was good to have our GM on site to provide clarification to the local service company performing the weld repair.

Alloy Engineering provided the parts, the repair procedure, and the expertise to advise this critical repair. The total time it took to complete the repair from the time we received the phone call to the last weld was 8 days (see figure C).

Fig C. This shows the final SS overlay repair weld

DETERMINING THE ROOT CAUSE

With every failure, it’s important to determine the root cause. Typically, knowing the root cause of a failure hopefully allows for changes to prevent future occurrences, or at least minimize the reoccurrences. In this case, there was suspicion of “acid reboiling;” the process gas condensing under certain pressure and temperature conditions. This was apparent from the initial visual examinations from the field inspections but needed to be confirmed. Additionally, there needed to be an understanding of why the “acid reboiling” occurred. In our quest for discovering answers, we would perform a metallurgical “autopsy” on the nozzle and interview our customer for operational concerns.

For the metallurgical analysis of the nozzle failure, Alloy Engineering used a third party lab to perform a visual examination, chemical analysis, and a microscopic evaluation. The lab cut the nozzle at multiple locations and noted severe corrosion along the bottom of the nozzle. This corrosion is indicative of liquid forming and collecting along the bottom of the nozzle. The chemical analysis, performed using an XRF Analyzer, confirmed the chemistry was consistent with 304 stainless steel. [Note that XRF systems cannot detect Carbon; therefore it is not possible to differentiate between straight grade, L grade, or H grade.] The microscopic examination had signs of an intergranular corrosion which indicates aqueous conditions (see figure D)

Fig D. The darkest colored area is the mounting resin, the next lightest color is the intergranular corrosion, and the lightest color is the base material

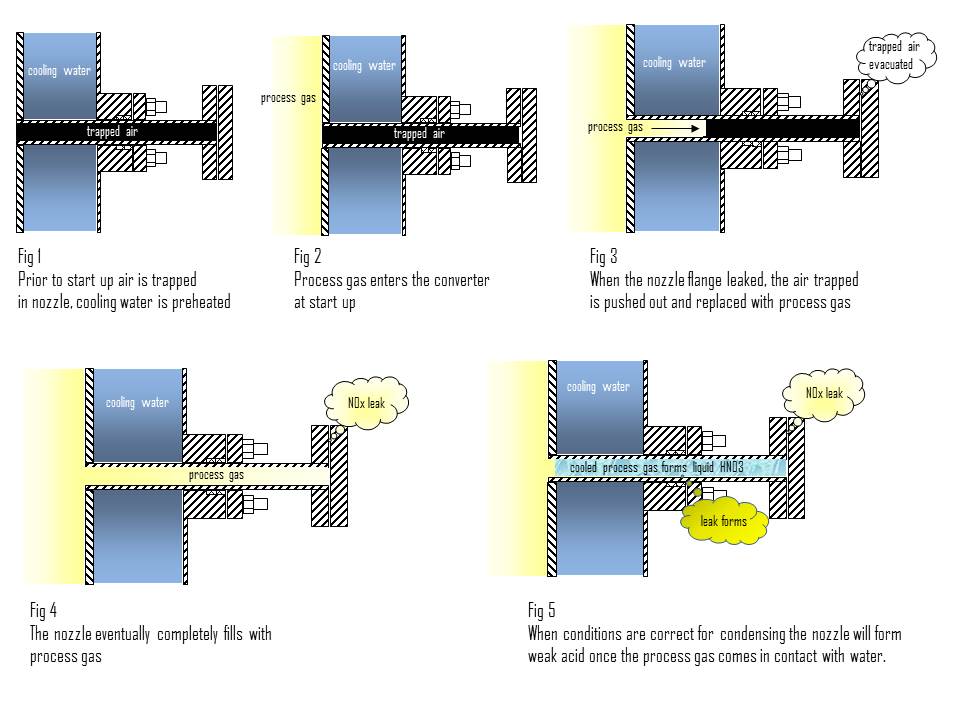

During conversations with the customer, Alloy discovered the end flange of the nozzle had a slight leak at start up and was allowed to leak for a time before being corrected. Our hypothesis is that the leaking flange allowed the trapped air in the nozzle to be pushed out of the nozzle and replaced with process gas, NOx. With the NOx in the nozzle, it was allowed to cool by the water jacket on the outside of the converter. The cooled NOx condensed and produced a weak nitric acid, HNO3. The results are evident.

SO WHAT’S THE “FIX”?

Unfortunately, there is not a permanent, 100% fix. From a maintenance perspective, care needs to be taken to ensure the correct gaskets are being installed and the flanges are properly tightened to avoid a process gas leak. From a mechanical design perspective, there are other possible materials to use; Alloy 825 being a common choice (although 304L is a close second). From a process design perspective, there are possible process changes that can be implemented, such as installing purge lines. Ultimately, the most important fix is for everyone involved, from designers to operators to maintenance personnel, to learn from this failure and be diligent not to repeat the same mistakes in the future.

Copyright

Copyright